The tried and true method (not to mention, Inexpensive) of tying down the frame and anchoring the pulling tower is back! OK it never really left, it's just with all the full frame racks out there they've just been forgotten.

You know the story...

Both your frame racks have heavy hits on them and are 3 days from completion. Then you get a fender bender walk-in that needs a couple of light pulls, no measuring, a little body and paint work. A one day turn-a-round... Sweet! Then you remember your racks that are 3 days from being free, you have no other way to make those couple of light pulls, and the customer can't wait. So he's out the door, and on his way to your competition. Has this happened to you?

Worry no longer...

We have them!

Floor Pots. Yes, Floor Pots, those little tails of chain that grew out of the floor at that shop you started

at all those years ago. We have them and yes we install them! Install them in any pattern of your

choosing, or choose from many standard patterns.

We have them!

Floor Pots. Yes, Floor Pots, those little tails of chain that grew out of the floor at that shop you started

at all those years ago. We have them and yes we install them! Install them in any pattern of your

choosing, or choose from many standard patterns.

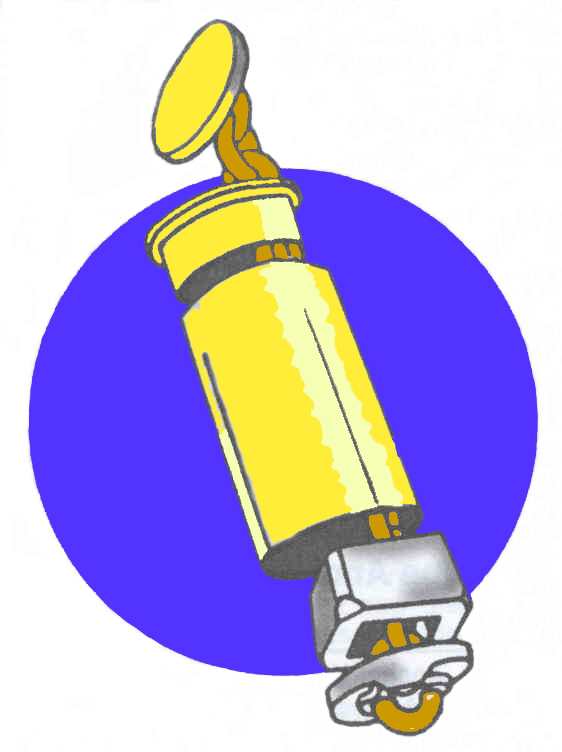

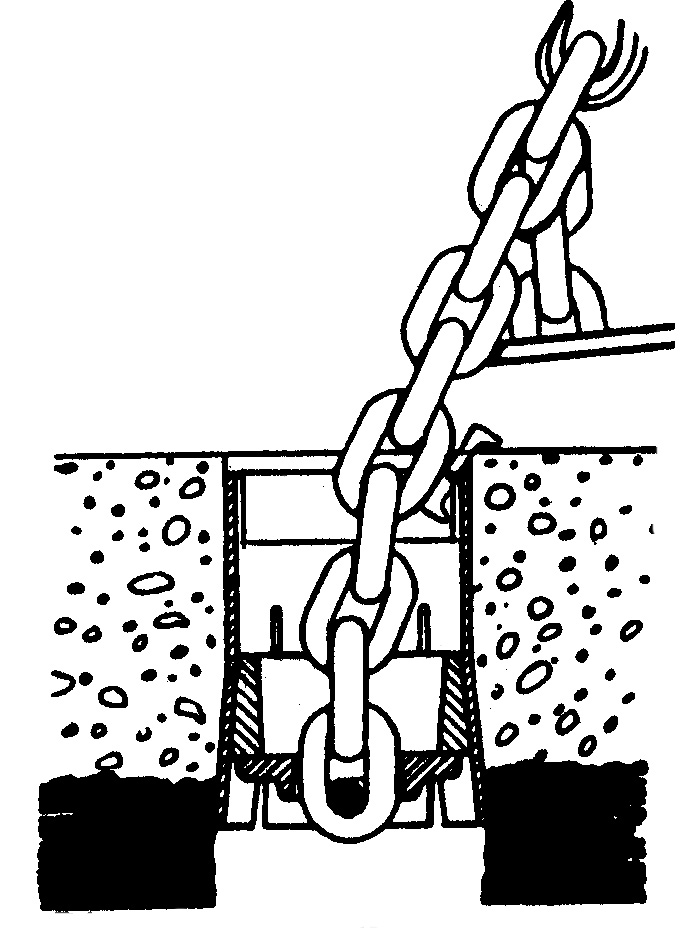

These cylinder-shaped, wedge-type anchors can be installed in your existing floor and create a tie-down frame stall for your shop in a jiffy, even in the middle aisle. So pull out of storage that floor system pulling tower your dad left you and put it to good use.

With our 3 1/2" diamond concrete core drill, the floor pots can be installed in existing floors and wedged into an immovable position so you can work in almost any position around a damaged vehicle.

The pot is inserted into the hole drilled in the concrete and a press forces the square wedge securely into the cylinder. Since the wedge is larger than the inside diameter of the cylinder, the slotted cylinder walls expand against the concrete, locking the cylinder into the floor. A protective insert ring at the neck of the cylinder prevents chipping the concrete around the top of the cylinder. Once installed, the tighter you pull the tighter it wedges. When the pot is not in use, the chain drops into the cylinder, pulling the cover in with it and creating a flush with the floor appearance. The covered pots create a smooth surface for wheeled or castered equipment and make clean-up and sweeping easy.

Please take some time to view photos of floor pots being installed below.

(Click on any photo to enlarge)

•

Home

•

• What's New •

Paint Booths

• Prep Stations

• Paint Mix Rooms •

Air Make-up Systems •

Air

Filters • Shop Curtains •

Welding

Blankets • Frame Benches •

Floor

Anchors • Pulling Accessories

•

Super Seal

Roll Door •

![]()

This page last updated on Thursday, August 04, 2022 08:14 AM .